Industrial projects

- 21/05/2019

>> Sloshing in the oil tank.

► Consider the behavior of oil in the case the tank truck change the speed suddenly.

► Multi-phase modeling.

► Run the simulation with tank baffles.

Simulation of sloshing phenomenon

► Consider the residual stress during welding.

► Evaluate the total distortion after welding.

► Propose a solution to resolve the problem.

Changing of temperature in the welding process

stress field in the welding process

Total distortion after welding

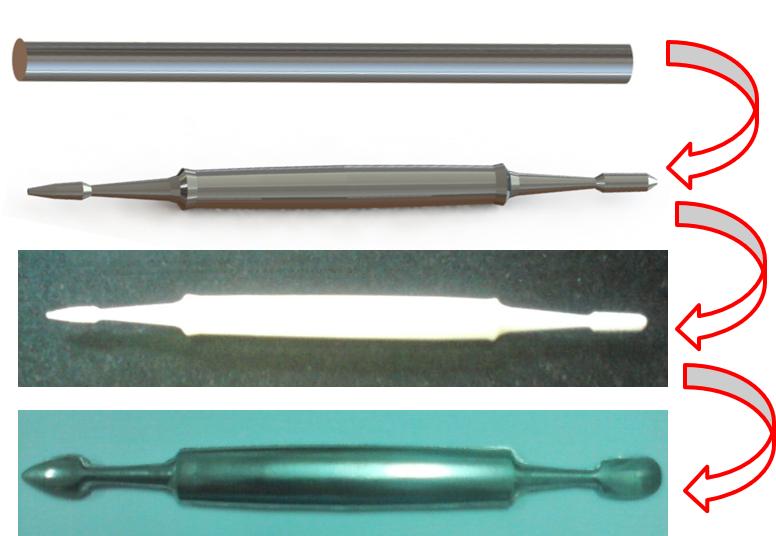

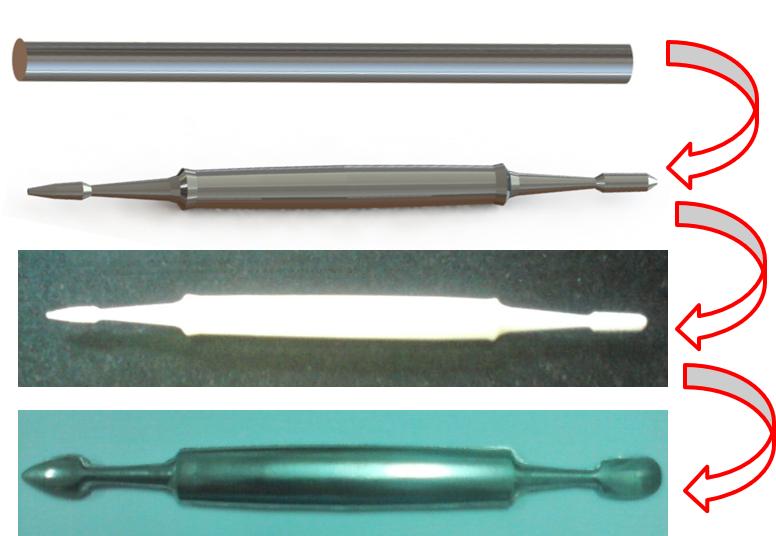

The workpiece, semi-finished and finished products before optimization

Equivalent stress field in the forging process

Initial workpiece -> Optimized workpiece -> 3D-printed prototype -> Experimental product

>> Cuticle pusher workpiece.

► Design and optimize the workpiece.

► Minimize the flash during the forging process.

► Select the processing method.

The workpiece, semi-finished and finished products before optimization

Equivalent stress field in the forging process

Initial workpiece -> Optimized workpiece -> 3D-printed prototype -> Experimental product

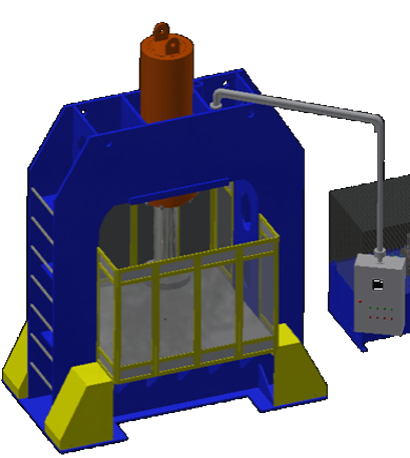

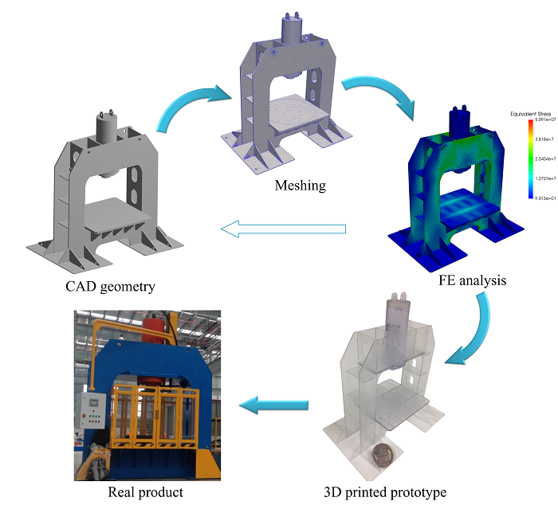

>> Hydraulic pressing machine - Camso Vietnam, VSIP2.

► The main frame is around 8 ton.

► Hydraulic cylinder pressing force 260 ton by 210 bar pressure.

► Check the strength of material.

► Improve the safety factor and decrease the weight of the machine.

3D design

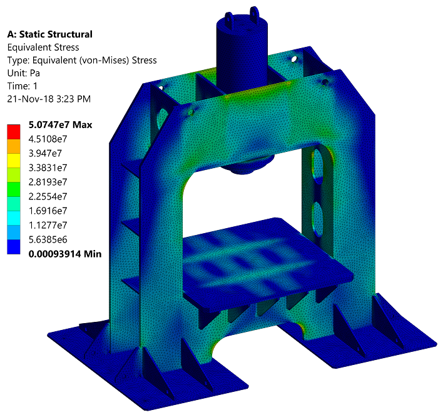

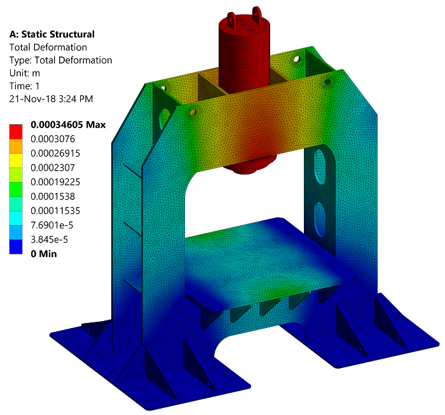

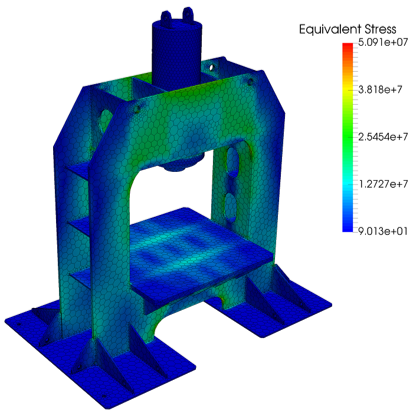

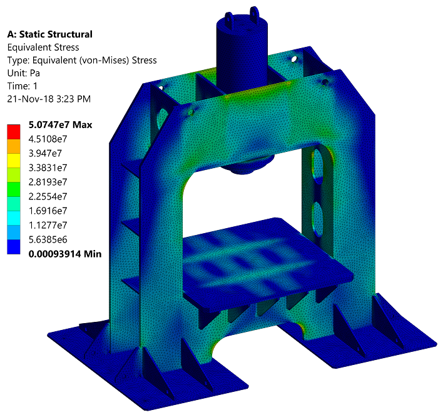

von-Mises stress field extracted from ANSYS solution

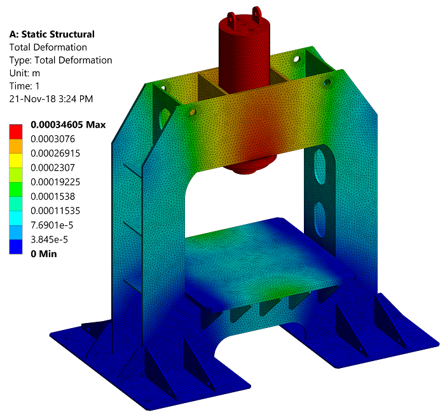

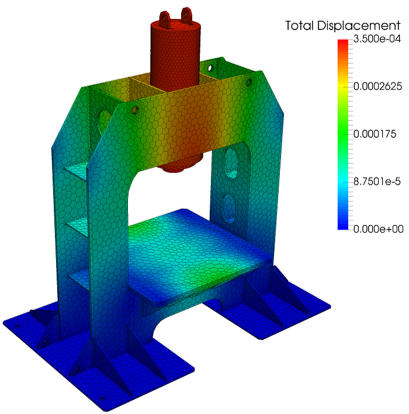

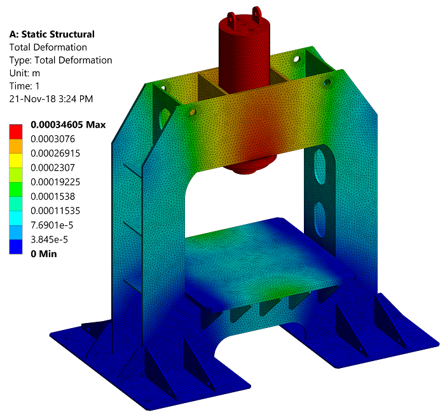

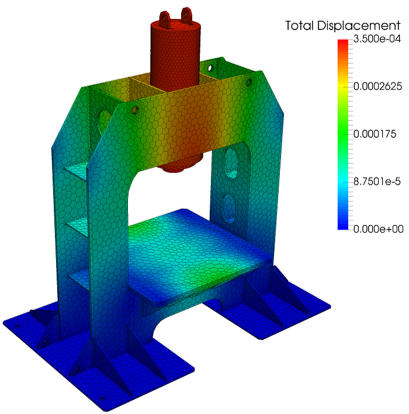

Total displacement distribution extracted from ANSYS solution

Total displacement distribution extracted from ANSYS solution

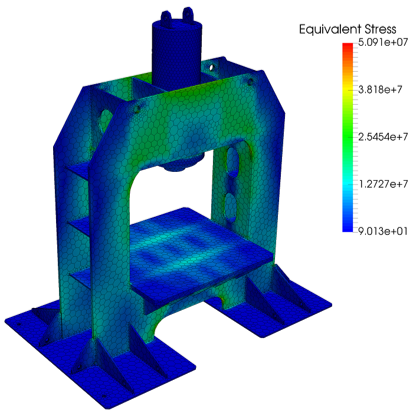

von-Mises stress using polyhedral element

Total displacement distribution extracted from ANSYS solution

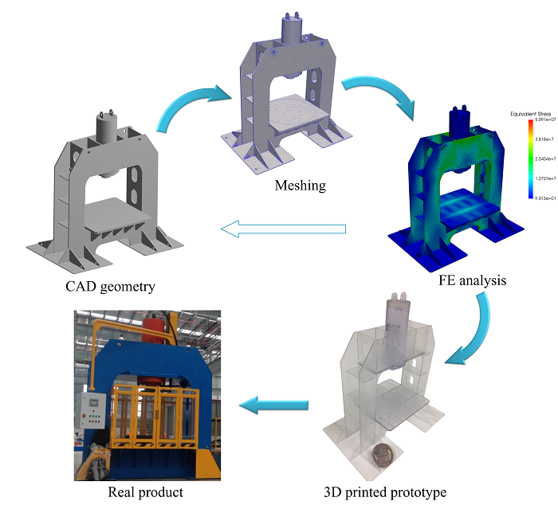

Cycle from model design to manufacture

von-Mises stress field extracted from ANSYS solution

Total displacement distribution extracted from ANSYS solution

Total displacement distribution extracted from ANSYS solution

von-Mises stress using polyhedral element

Total displacement distribution extracted from ANSYS solution

Cycle from model design to manufacture